General

General

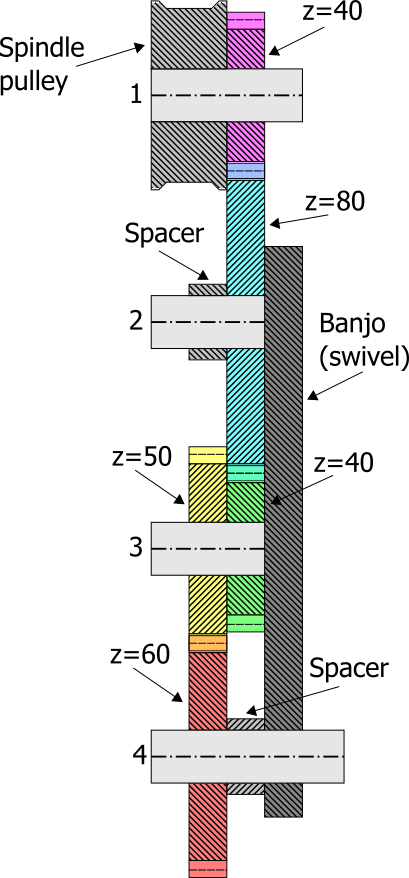

This main purpose of this calculator is to determine how to setup lathe change gears for a threading operation. The calculator assumes there is a mechanism by which the distance between the first and last shaft to be varied (banjo/quadrant). In addition, the calculator can be used for almost any type of gear train applications. For instance for gear hobbing or automotive gearbox design (but this may require abusing the input fields). The illustration shown here provides an example of how a lathe might be setup.

Required input

Leadscrew lead specifies how far the lathe carriage moves with one revolution of the leadscrew (shaft 4 in the illustration). The unit can be either in mm per revolution or TPI, meaning how many turns of the leadscrew per inch of travel.

Shaft count is the number of shafts used in the gear train, where the first is normally the spindle and the last the leadscrew (the illustration has 4 shafts)

Change gear set is a comma-separated list of available change gears. If multiples of the same gear size exists, both should be included in the list.

Input gear set is a comma-separated list of gears that can be used on the first (often spindle) shaft. This is separate, because often that gear cannot be changed. In the case that there is no difference between the first gear/shaft and the rest, the same as change gears should be checked.

Desired lead is the target of the calculation and can be in either mm per first shaft (spindle) revolution or as TPI, i.e. turns of the first shaft (spindle) per inch of travel.

Gear module specifies the module (or diametral pitch DP) of the gears. The gear module is required to apply some of the contstraints, e.g. distance between shafts.

Input gear adjacent size specifies the size of e.g. a pulley (as in the illustration) beside the input gear (shaft 1), which limits the size the gear(s) on the following shaft can have

Spacer size is the size of the bushing in case the is only one gear on a shaft.

Minimum shaft distance and Maximum shaft distance specifies the minimum and maximum accepted distance between the first and last shaft, respectively. This is requried to ensure the used gears are sufficiently large to reach all the way from the first to the last shaft, but not so large that they don't fit on the banjo/quadrant